Column

Febrero 16, 2022

FabCafe Global Editorial Team

“Action, not prestige” is the idea behind the crQlr Awards, which aim to not only recognize but catalyze the many diverse players working towards a circular economy. For the inaugural Awards in December 2021, judges and winners attended sessions hosted by five cities over two days. More than an awards show, the crQlr Summit is a stage for open feedback and knowledge exchange between those working on the global frontlines of circular design.

This report brings you highlights of the session hosted by FabCafe Taipei, with the theme of a multidisciplinary approach to the circular economy. Transforming the conventional economic model requires us to step outside our professional fields and engage with people from other disciplines. The session brought together judges and winners from industries as diverse as architecture, materials, food, automobiles and tourism. Let’s meet them.

The judges of crQlr Awards.

The 2021 crQlr Awards were judged by a panel of 19 sustainability experts and practitioners. Several judges joined each session of the crQlr Summit to discuss the entries that caught their eye and give feedback to the winners. Judges attending the Taiwan session were:

Tim Wong

Tim is a co-founder of FabCafe Taipei and Loftwork Taiwan, co-organizers of the crQlr Awards. He has dual Master degrees in Architecture and Urban Design from Harvard Graduate School of Design and has worked on urban design projects across Asia, North America and the Middle East.

David Benjamin

David is Associate Professor at Columbia Graduate School of Architecture, Planning and Preservation. He is also Founding Principal of The Living, an award-winning design studio that explores and prototypes new uses for biomaterials in architecture.

Richard Ekkebus

Richard is the Culinary Director at The Landmark Mandarin Oriental, Hong Kong. He is a pioneer of sustainable cuisine and ethical sourcing, and his restaurant Amber has earned the Sustainable Restaurant Award in addition to two Michelin stars.

Kelsie Stewart

Kelsie is Chief Community Officer of the FabCafe Global network. As well as being a judge and co-organizer of the crQlr Awards, she also served as a moderator during this session.

The 2021 crQlr Awards saw a total of 63 prize-winning projects from over 200 entries. Several winners joined each session to discuss the challenges they’ve faced – and often still face – implementing and scaling their projects. Representing the winners at the Taiwan session were:

Dr. Noryawati Mulyono, Co-founder and CEO of Biopac

Biopac is an Indonesian SME that uses proprietary technology to manufacture seaweed-based bio-packaging. Judges praised its efforts to improve the livelihood of seaweed farmers and create a cycle in which more seaweed is cultivated, absorbing more carbon, which then forms the material basis for the biopolymers used in the packaging. Biopac was awarded the Amber Prize by judge Richard Ekkebus, who commented:

Coastal ecosystems like mangroves, seaweeds and seagrasses are known for storing carbon. Often called ‘blue carbon’ ecosystems, they can take up to 20 times more CO2 per acre than forests on land. The ocean draws in about 30% of the atmosphere’s CO2, therefore seaweed plays an important role in absorbing carbon. Seaweed is also delicious and full of umami (one of my favourite ingredients to work with), while seaweed farming has no negative impact on its environment. Seaweed grows fast, and this project shows that we use seaweed to make packaging.

INOW is an educational program located in Kamikatsu, Tokushima, the famous “zero-waste” village of Japan. Having no central waste disposal system, Kamikatsu’s residents must separate their garbage into 45 different categories to be recycled instead. This unique setup draws international attention to the village, and visitors now have the opportunity to experience Kamikatsu’s system for themselves. INOW was awarded the Good Life Prize by judge David Benjamin, who commented:

This remarkable and quietly radical project gives us an optimistic view into a good life that is possible beyond our current wasteful practices and also beyond an incremental approach to improvements. Circularity is about a way of life as much as it is about technology or materials. INOW gives us a sense of the radical transformations needed to address the immensity of the climate change emergency. It also gives us a window into the wonderful and appealing results of changing the way we live. And it is a poignant reminder of “lost wisdom of the past” and the role that traditional, indigenous, and vernacular practices must play in a meaningful transition to a circular economy.

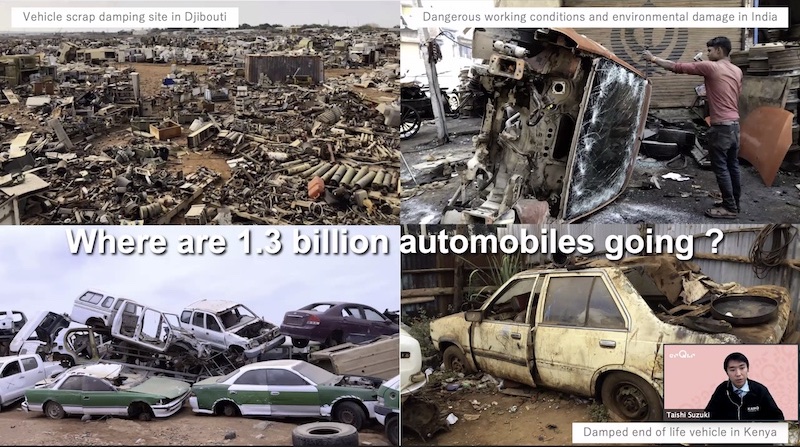

Kaiho Industry of Kanazawa, Japan was recognized for its ambitious drive to expand auto recycling on a global scale. This has included developing an international quality standard for used vehicle parts and providing education in vehicle recycling to 200 trainees from around the world. Kaiho was awarded the Re-Work Prize by judge David Benjamin, who commented:

This project embodies the essential and beautiful idea that circularity and re-use are compatible with meaningful labor and good jobs. Operating at multiple scales, the project is both local and global. It engages a local community and way of life, as well as a global impact (1.3 billion cars in the world! More than 1 million used cars exported to developing countries every year!). And it offers a compelling new version of global connection based on reuse and recycling rather than extraction and consumption. It is very impressive to see the project demonstrating some of the technical details required to make circular approaches work, including international standards, cooperation between companies, and education and re-training.

In the first half of this session, judges and winners talked us through their own projects and how they’re responding to sustainability challenges in their industry or locality. Those presentations can be seen in full in the video below. The second half was given over to feedback and discussion, with some of the key takeaways highlighted here:

David: The three winning projects here are all doing something important, but all doing something slightly different. I think it’s exciting to know that we have these great models. We need this great work on new materials and biomaterials. We need this great work on reusing materials. And not only that, but we can think about new ways of life and new jobs in terms of auto recycling or manufacturing new biomaterials for packaging.

Richard: It was a very hard job to go through the 200 or so submissions. There were some incredible ideas, so it was a very daunting task to find a winner. I think everybody that has submitted has a winning project, and I hope to see much more of this moving forward and materializing. I think in the world we’re really focusing a lot on mining and on fabricating all sorts of resources. We have been failing ourselves in finding systems, in reutilizing better and repurposing better within our businesses. Reading through all the submissions, I felt a very reassuring sentiment that there is hope for the future.

Tim: I really enjoyed the wide spectrum of work all the speakers are doing today. I think all of you guys have already proved that you’re the pioneers in your own industries and your own practices. And then you are really willing to go that extra mile, not just for your own benefit, but actually seeing the bigger picture of how we should live as a society.

Richard: My question to Taishi of Kaiho Industry would be: what part of a car is not recyclable? I can imagine there must be some parts that are very challenging, and I would love to hear about that.

Taishi: In Japan, it’s very hard to recycle plastic, rubber, glass, and car seats. We can segregate the materials, but there’s no technology for material recycling. Also, recycling costs too much, so it doesn’t pay off in the market.

Richard: I read a very interesting article about how tires were recycled in Africa and used in asphalt roads, which really makes sense. The wheels that are driving on the roads are reused after their cycle of life into the road itself. So maybe that’s where there’s an opportunity in Japan?

Taishi: I think there is some recycling technology, like in asphalt, but the market volume is small and the number of end-of-life tires is quite a lot, so we need to find some market for recycling.

David: At COP26, the vice president of sustainability from BMW said something to the effect of how we need to rethink composite materials, which we used to think would be the future. They’re higher performance, lighter in weight, and they certainly can be remarkable. But it was fascinating to hear one of the champions of composite materials, a car company like BMW, saying we need to rethink composite materials in order to allow for more circular approaches. Hopefully, Taishi, you can increase the awareness of the manufacturers themselves about the need for playing their role in this circular ecosystem.

David: Circularity is just as much about a way of life as a technical approach to energy and materials. We really need to change our way of life to address the immensity of the problems. And that can be wonderful and appealing, not just a sacrifice. I thought it was just so exciting to see the INOW project being so generous about inviting people in. Hopefully that can have a multiplier effect when people leave that experience and go back to all kinds of different homes around the world.

Linda: Thank you! In the media, Kamikatsu village is portrayed as this perfect example of sustainability, but we don’t want people to think this is something only we do that is not possible for someone else. Essentially, we use the word zero waste, but this is a misnomer because “gomi-zero” in Japanese means “no garbage”. So the idea was that we would prevent garbage from going to the landfill. But this doesn’t actually stop us from producing waste because everything that everyone purchases in the village is still from the production line of the larger society. And so one of the things that we’ve really learned is how recycling works. Right now, Kamikatsu’s recycling rate is at 80%, and we were not able to get to that extra 20% because there are so many materials that are just made for one-time use. The onus is on the producers to start looking at how they’re creating their products, which are designed basically to be thrown away.

Richard: In hotel operations, we are animals of convenience. When we started to eliminate single-use plastics, we identified a lot of things we were using on a daily basis that contain plastic, such as wipes, sponges, cling film, vacuum bags, and so on. On the journey to eliminate single-use plastics, we basically went back in time. How did our grandparents deal with these kinds of problems? For example, you can go back and find an old type of sponge that is 100% plant-based. Very often these are made by companies that were out of business for a long time because they were conceived as old fashioned. Basically, we have been able to create this circular economy around these small companies that were struggling and all of a sudden are thriving again because what we did 50 years ago was actually the right thing to do.

Nory: Biopac doesn’t sacrifice the convenience and time of consumers. With reusable packaging, for example, people have to keep in mind when they go shopping to bring the empty package. Our product is more convenient, but the real challenge is the cost. We hope later to have at least one distributor in every country so we can sell the product in bulk, which is more efficient in terms of transportation cost.

Linda: We actually tried to order it from your company because we also run a zero-waste cafe in Kamikatsu. We’re a small operation, so by ordering a small amount the cost was just not effective. And I think that’s also a consumer problem. We are so used to things being so cheap that we don’t actually know the real value of things. System changes aren’t happening because companies are not asked to stop producing single-use products. The onus is on the individual to be a better person, and so we create this idea that if you are not being sustainable, you’re the one who is the problem rather than the system itself.

David: We want government standards, regulation and incentives to help price things properly. For example, if there was a tax or a penalty for waste or carbon emissions, then immediately, Nory, your product would be the least expensive. It just shows that our systems are already designed. I mean, it’s not like our systems are neutral now. They’re designed against circularity in some cases. I was hearing at COP26 that all kinds of businesses are asking the government to create standards and regulations. They understand that their long-term survival requires them to be more circular and more sustainable.

Richard: On a positive note, Hong Kong is pushing for new legislation to make all takeaway packaging home compostable. There’s definitely a market for Nory’s company in Hong Kong, which is the world capital of takeaway food. People do not cook a lot at home, and particularly during the pandemic the amount of takeaway has significantly grown. To see this legislation being pushed is a very positive development in Hong Kong.

Tim: Linda, one thing I want to bring up is that, before the pandemic, FabCafe did a project in Hida, Gifu Prefecture, where we brought students into rural communities. When we think about urban design, it’s not just from a building perspective, but also about working with the community. There are innovations to be made by reconnecting these traditional systems with new technologies or design thinking.

Linda: We want to build a community space in Kamikatsu for people who are thinking about sustainability. A space where people can come and learn, and also connect with each other. We actually opened our business during the pandemic so we’ve never had any inbound customers because the borders of Japan have been closed. As soon as it’s possible to travel, we really want to start getting more people connected and gaining hands-on personal experience, which is much more impactful than learning about it through a publication.

Tim: And one thing I want to talk about with David is the analytical model that you built. The model goes beyond just the construction phase and into the operational phase, meaning the occupancy and the usage of the building. In that case, then we can really see the performance not just from a building perspective, but actually from a user perspective.

David: I think it’s going to be so important, as we’re scaling up the best approaches, to understand the data at the right resolution. What’s the data of the carbon emitted for the shipping? What’s the data we have to work with as we’re occupying buildings? There’s this incredible concept called material passports. You can give a unique identity to a building element like a beam or a brick, but it could also be a specific car tire that’s been on the road for this amount of time and has these cracks in it. If you give a material an identity, then it’s easier to change the mindset in terms of reusing it. And that’s going to require some data approaches, so there’s this hybrid potential of returning to the wisdom of older people and cultures on the one hand, and at the same time using technology to think through challenges of scaling up and make the best decisions.

The role of materials in the circular economy happens to be the theme of the next session hosted by FabCafe Kyoto. Continue to the next report, or watch the entire Taiwan session below.

Want to know more about the projects above? The entire Taiwan session, including presentations, feedback and discussion, can be viewed here:

crQlr is a global consortium that supports the practitioners and future creators of a new society based on a circular economy. To enquire about our awards or to request support for your own circular project, get in touch with us here.

-

FabCafe Global Editorial Team

This articles is edited by FabCafe Global.

Please feel free to share your thoughts and opinions on this article with us.

→ Contact usThis articles is edited by FabCafe Global.

Please feel free to share your thoughts and opinions on this article with us.

→ Contact us