Exhibition

- #Finished

- #Entrance Free

"Weaving the Future" is an exhibition of the process and prototypes of a project that has explored new possibilities for textiles as materials, with a focus on "Japanese-style Jacquard" and "e-textiles".

Fri, March 17, 2023 – Tue, March 21, 2023 UTC+09:00

11:00 – 18:00

Kyoto Saga University of Arts | View on Google Map

free

WHAT is the TSS 2022 ?

The Textiles Summer School (TSS) is an ongoing collaborative project involving national and international designers, textile engineers, textile producers and materials scientists from Japan and overseas.

TSS 2022 is organised by a committee of volunteer members from different disciplines and will consist of two parts – the first an online lecture series by leading international textiles and materials practitioners, which was open to all. The second part was a hybrid online/physical workshop held in collaboration with designers, research centres and businesses involved in the textile industry in Japan and internationally.

(*This project is supported by a grant from the Pola Art Foundation)

*This page contains details of the exhibition. Please click here for information on the online lecture.

Exhibition Overview

– Dates: March 17 (Friday) – March 21 (Tuesday), 2023

– Venue: Gallery “Art Space Saga” at Saga University of Art

– Free of charge, no reservation required

Exhibit Contents

– Presentation (video and panel) by each team that participated in the workshop

– Prototypes and samples of materials produced through collaboration between the teams participating in the workshop and Nishijin and Tango textile businesses.

– Video clips introducing the unique techniques and stories of the Nishijin/Tango collaborators

(These photos are scenes from an exhibition held at FabCafe Kyoto in January 2023.)

Exhibitor (the teams participating in the workshop)

Loughborough University Team

Leader: Dr. Tincuta HEINZEL

Collaborator: Kyoto Prefectural Institute for Northern Industry, Usui Orimono Co.

TU Delft Team

Leader: Professor Holly McQuillan

Collaborators: Kyoto Prefectural Institute for Northern Industry, Usui Orimono Co.

UAL [University of the Arts London] Team

Leader: Professor Caryn Simonson, Claire Anderson

Collaborators: Katsura-Kigyou Ten, Morisan Co.

Osaka University of Arts Team

Leader: Professor Ayumi Kizuka

Collaborator: Morisan Co.

Kyoto Saga University of Arts Team

Leader: Professor Kaori Ueda

Collaborators: Katsura-Kigyou Ten, Morisan Co.

The University of Shiga Prefecture Fujiki Team

Leader: Professor Yosuke Fujiki

Collaborator: Tamiya Raden Ltd.

The University of Shiga Prefecture Morishita Team

Leader: Professor Aoi Morishita

Collaborator: Yamasaki Orimono Co.

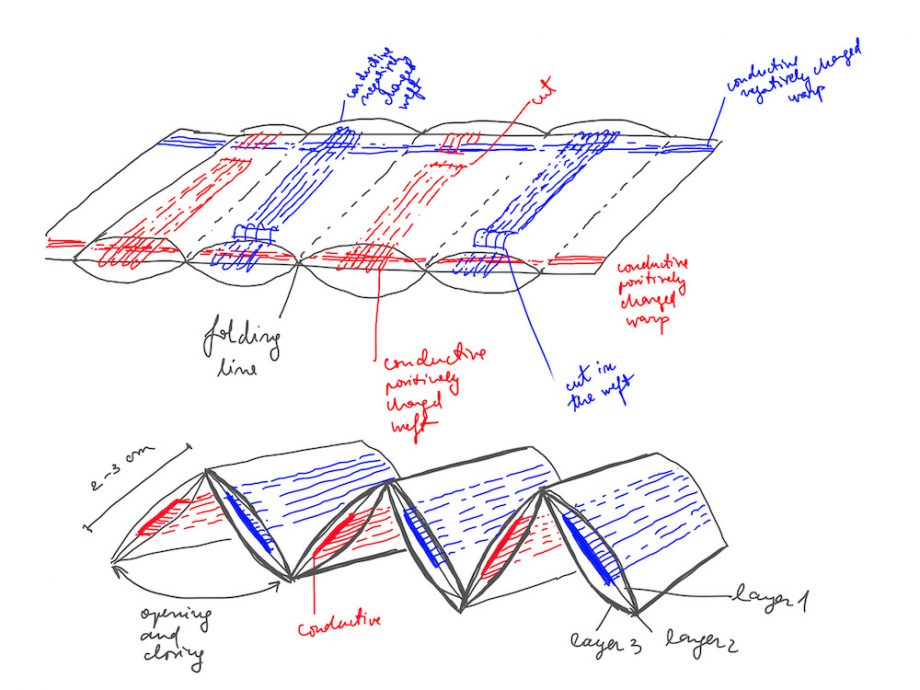

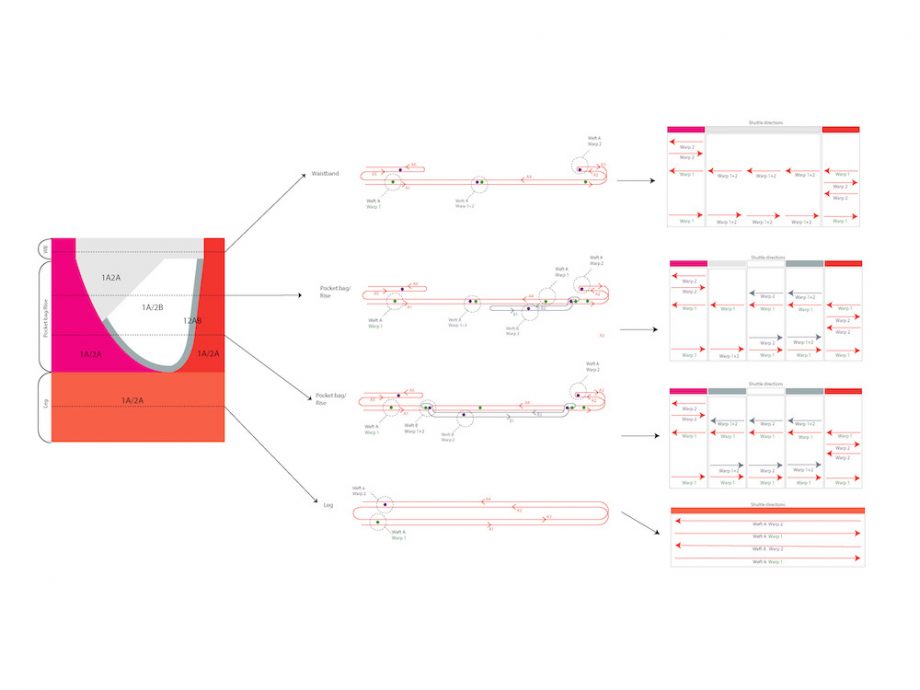

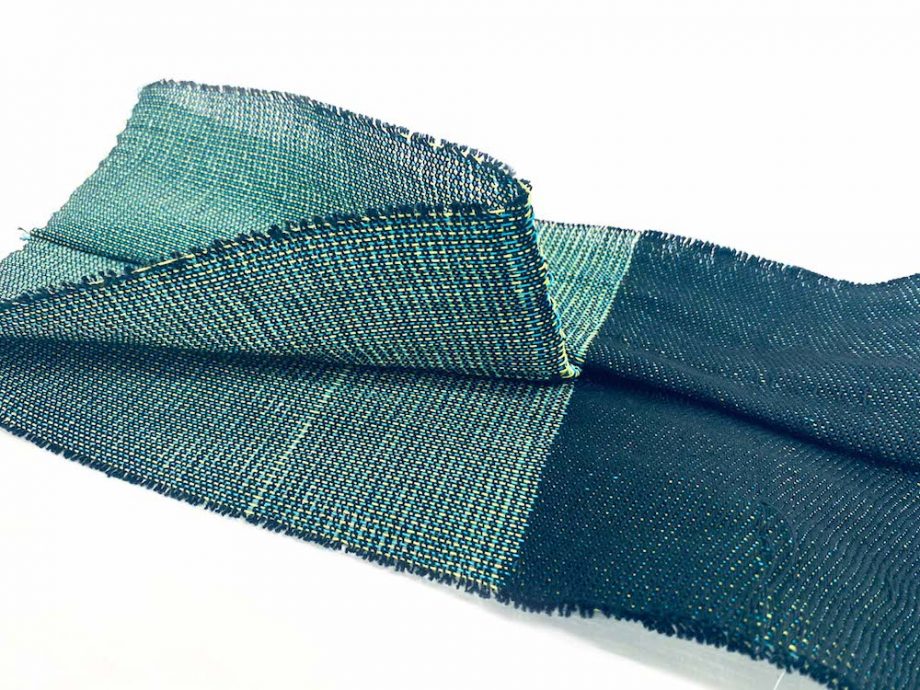

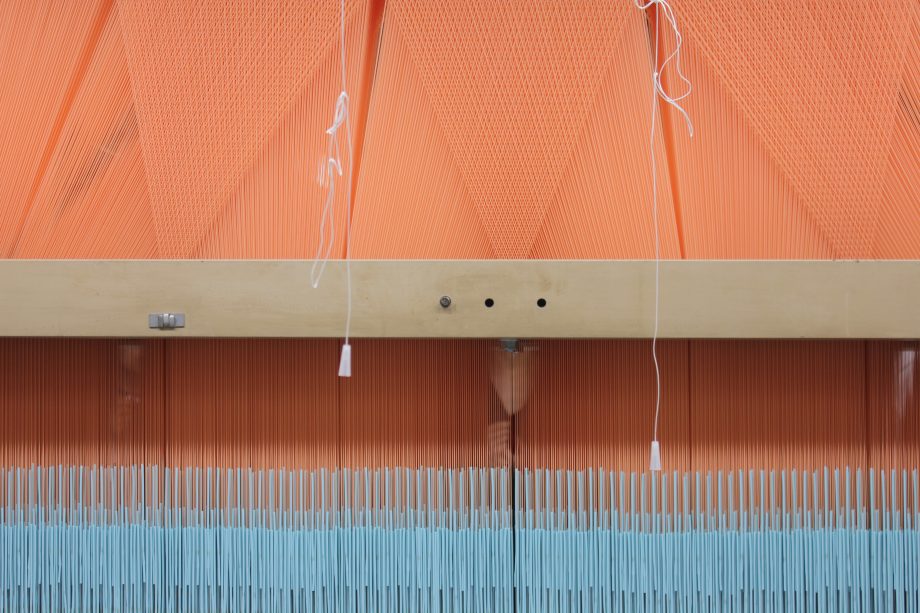

(The workshop involved a hybrid online/offline exchange of ideas and prototyping by a multinational university team with textile businesses in Nishijin and Tango over a period of about three months. These images are part of the prototyping process, including research and idea sketches.)

THEME

TSS2022 explored new possibilities of textiles from a materials standpoint, with a focus on ‘Japanese Jacquard Weaving’ and its potential for the creation of ‘e-textiles’ or experimental textile works.

Eight online lectures were held as an intensive, interactive learning programme. Japanese and international practitioners presented subjects related to the overall theme from a variety of perspectives embracing sustainability, the luxury market, materials research and speculative design and e-textiles. Open to all on payment of a fee.

The Unique Characteristics of the Japanese Jacquard

Background

Until the introduction of the European Jacquard loom in the Meiji Period, Japanese looms and weaving practice were based on the narrow-width cloth required for the production of kimono and obi. They could not produce the broader fabric widths required for the international market. For the European Jacquard loom, fabric width, multiple repeats, speed and optimisation of weaving, along with reduction of costs were of key importance. In Japan, the ability to produce intricate weave patterns with minimal repeats over a 40cmsurface on a loom, which could physically fit into the limited spaces of a highly specialised cottage industry were the prime considerations.

Thus, the Japanese Jacquard developed as a context-specific hybrid, which operated on the same basic principles as the European Jacquard but which integrated Dobby and other mechanisms such as the botou and fumise. These allowed a wide vocabulary of specific weave techniques and yarn processes to be innovated whilst retaining traditional methods of pattern drafting. By bringing together the advantageous aspects of both systems, it allows a degree of customisation and scaling up or down depending on circumstances not possible in Western Jacquards. It is why it has become a focus of interest for experimentation among textile designers and artists in Japan today.

Some Japanese Jacquard Advantages for Experimentation

A variety of yarns can be used on the shuttle loom, including high-twist yarns, relatively thick yarns and specialist hybrid yarns like the tape yarns created by Tamiya Raden from finely sliced abalone on washi paper. Experimental yarns of this type, in which material commonly not used for weaving is blended or spun with a yarn component, open new avenues for textile designers.

The weft yarns are not automatically cut on both sides as in the Western Jacquard, but remain connected in a single line until the end of the shuttle tube. This factor and the ability to use thicker yarns than a Western Jacquard enable the use of conductive yarns, the creation of seamless looped fabric for whole garment production as well as multi-layered fabric – degrees of customisation and innovation vital to the development of new fabrics, particularly for the luxury market. This has made the Japanese Jacquard a focus of interest to those involved in the emerging areas of e-textiles and sustainable textiles.

Intelligent Textiles(e-textiles + Smart textiles)

Smart textiles can be defined as textiles that are able to sense and respond to changes in their environment. They may be divided into two classes: passive and active smart textiles Passive smart textiles, which are sensors and can only sense the environment; Active smart textiles, which can sense stimuli from the environment and also react to them; simultaneously with the sensor function, they also play an actuator role; Very smart textiles, which are able to adapt their behaviour to the circumstances.

Koncar, V. 2016. Smart Textiles and their Applications. Woodhead Publishing.

Intelligent textiles can be defined as those that have specific properties generated through the choice of yarn/material, spinning and weave process and the fabric’s subsequent treatment. Chrimen (silk crepe) is one such traditional example.

Collaborators

Tango Team

Kyoto Prefectural Institute for Northern Industry

As a research facility run by the Kyoto Prefectural Government, it is responsible for the support and development of the textile industry in Tango. It has weaving machines and equipment for weaving, dyeing and twisting yarns of all ages, as well as testing facilities and a textile archive. It can also process yarns for weaving and is equipped with an Haccho twisting machine. Haccho high-twist yarn is twisted using a method unique to Japan and is an essential material for Tango Chirimen.

- Type of fabric: Tango crepe, obi fabric, Western-style jacquard and many others.

- Weaving width: 40 cm – 130 cm

- Warp yarn type: raw silk

- Other: designs can be made into data

Tamiya Raden Ltd.

Has a history of collaboration with many luxury brands and owns a wide range of weaving machines.

- Type of weaving: raden-ori (a weaving technique devised to weave in raden without crushing the tape-like threads)

- Weaving width: 32 cm – 97 cm

- Type of warp yarn: silk

- Other: designs cannot be made into data

Usui Orimono Co., Ltd.

Also produces experimental fabrics using shrinkage and high-twist yarns, which are the principles of the chirimen crepe process, on a white polyester crape fabric. As it is a white fabric, printing on the surface is possible.

- Type of fabric: woven on a dobby loom, crepe fabric

- Weaving width: 110 cm

- Warp yarn type: polyester

- Other: no Jacquard looms

Nishijin Team

Kyoto Municipal Institute of Industrial Technology and Culture

An industrial support organization that provides comprehensive research, testing, training and other technical support to the textile industry. It has created a data format for operating Japanese-style Jacquards (CGS format) and continues to sell general purpose software. Suitable for collaboration with overseas research institutes, e.g. for data compatibility development.

- Textile types: gold brocade (vestments: textiles mainly related to Buddhism), obi fabrics, Western-style jacquards and many others

- Weaving width: any width

- Type of warp: silk yarns

- Other: designs can be converted into data for Jacquard, but samples cannot be woven

Katsura-Kigyou Ten

Japanese-style Jacquard looms can be used. Japanese-style loom structure, but can weave wide widths. Also, gold leaf is woven using a spatula. Taking advantage of hand weaving, weaving with special weft yarns that cannot be woven on an automatic loom is also possible.

- Type of fabric: gold brocade (vestments: textiles mainly associated with Buddhism)

- Type of loom: Japanese-style Jacquard handloom

- Weaving type: handloom only

- Weaving width: 70 cm

- Warp yarn type: silk yarn

- Other: designs can be made into data

Morisan Co., Ltd.

The company makes traditional gold brocade fabrics. Patterns can be woven on a twill or satin ground using golden threads or slit yarn for the weft. New patterns can be made based on existing patterning; colour matching with Pantone is done visually. Up to eight weft colours are possible and the warp is white or navy blue. Design guidelines can be provided for designers.

- Weaving width: 70 cm

- Type of loom: Japanese Jacquard loom

- Other: designs can be converted to data

Yamasaki Orimono Co.,Ltd.

Established in 1929. The company is mainly engaged in the production of mounting strips for hanging scrolls and other objects. Omoteso sakibi refers to textiles used for making scrolls and hanging scrolls, or for making folding screens and fusuma sliding doors by attaching them to wooden frames. It belongs to a type of Nishijin brocade fabric (kinran) with a fabric width of approximately 70 cm. The company also produces high value-added fabrics for couture. Main overseas customers are Taiwan and China.

- Type of fabric: gold brocade (surface decoration strips: mainly used for hanging scrolls, etc.)

- Weaving width: approx. 70 cm.

-

With a grant from

-

Cooperation

京都府織物・機械金属振興センター

地方独立行政法人 京都市産業技術研究所

西陣織工業組合 金蘭振興委員会 -

Support

京都市 / Kyoto City

Contact

If you have any questions about this event, please send an email to the following address. (Contact: Kinoshita)

info.mtrl@loftwork.com

-

Julia Cassim

Arts columnist for the Japan Times from 1984 to 1999, from 2000 to 2014, Cassim initiated and ran the influential ‘Challenge Workshops’ programme at the ‘Helen Hamlyn Centre for Design’, Royal College of Art (RCA). A leading authority on inclusive design, she has organised and run many international context-specific workshops to share inclusive skills and knowledge, and in 2010 was named one of the ’50 most influential people in the world of design’ by the UK’s ‘Design Week’ From 2014 to 2019, KYOTO Design Lab at the Kyoto Institute of Technology – she was involved in a number of progressive projects as a specially-appointed professor in charge of establishing a cross-disciplinary design centre for design innovation. Her projects there have received numerous international awards, including the Red Dot Design Award and the Dutch Design Award.

(Photo by Tian Khee Siong)

Arts columnist for the Japan Times from 1984 to 1999, from 2000 to 2014, Cassim initiated and ran the influential ‘Challenge Workshops’ programme at the ‘Helen Hamlyn Centre for Design’, Royal College of Art (RCA). A leading authority on inclusive design, she has organised and run many international context-specific workshops to share inclusive skills and knowledge, and in 2010 was named one of the ’50 most influential people in the world of design’ by the UK’s ‘Design Week’ From 2014 to 2019, KYOTO Design Lab at the Kyoto Institute of Technology – she was involved in a number of progressive projects as a specially-appointed professor in charge of establishing a cross-disciplinary design centre for design innovation. Her projects there have received numerous international awards, including the Red Dot Design Award and the Dutch Design Award.

(Photo by Tian Khee Siong)

-

Kaori Ueda

Associate professor, Kyoto Saga University of Arts

Based in Kyoto, Kaori Ueda is textile designer and researcher specializing in weaving and Associate Professor at Kyoto Saga University of Arts. A graduate of the Royal College of Art (RCA) in 2007, she returned to Japan and began researching traditional textile design here.

Her research is practice-based rather than theoretical using actual design methods drawn from evidence in historic books and materials. She has recreated Old chirimen fabric to compare its quality with current chirimen fabric and show its material qualities outside its usual cultural context of the kimono.

Her other interest is in loom history and the differences between the European Jacquard and those used in Japan for traditional clothing.

https://www.kyoto-saga.ac.jp/about/teachers/2156[ Photo: Masaki Kawabata]

Based in Kyoto, Kaori Ueda is textile designer and researcher specializing in weaving and Associate Professor at Kyoto Saga University of Arts. A graduate of the Royal College of Art (RCA) in 2007, she returned to Japan and began researching traditional textile design here.

Her research is practice-based rather than theoretical using actual design methods drawn from evidence in historic books and materials. She has recreated Old chirimen fabric to compare its quality with current chirimen fabric and show its material qualities outside its usual cultural context of the kimono.

Her other interest is in loom history and the differences between the European Jacquard and those used in Japan for traditional clothing.

https://www.kyoto-saga.ac.jp/about/teachers/2156[ Photo: Masaki Kawabata]

-

Tomohiro Inoue

KYOTO Design Lab, Kyoto Institute of Technology / FABLAB Kitakagaya

Tomohiro Inoue teaches digital fabrication to citizens at FABLAB Kitakagaya. His main area of activity is making things and creating things using digital fabrication, and he is developing a movement to promote the makers movement so that it does not become a transient movement.

https://fablabkitakagaya.org/

YouFab Global Creative Awards 2015 FINALISTSTomohiro Inoue teaches digital fabrication to citizens at FABLAB Kitakagaya. His main area of activity is making things and creating things using digital fabrication, and he is developing a movement to promote the makers movement so that it does not become a transient movement.

https://fablabkitakagaya.org/

YouFab Global Creative Awards 2015 FINALISTS -

Kosuke Kinoshita

Loftwork Inc. / MTRL・FabCafe Kyoto Marketing and Produce

Kosuke Kinoshita has been involved in “MTRL (Material)”, which supports co-creation and innovation of manufacturing companies using materials as a starting point, and “FabCafe Kyoto”, a community base where various creators, researchers, and companies gather with the keywords of technology and creation, since its launch. Through online/offline workshop management and exhibition planning production, he is practising “creating a place where chemical reactions occur” and “designing contexts that connect things from different fields.

https://loftwork.com/jp/people/kousuke_kinoshitaKosuke Kinoshita has been involved in “MTRL (Material)”, which supports co-creation and innovation of manufacturing companies using materials as a starting point, and “FabCafe Kyoto”, a community base where various creators, researchers, and companies gather with the keywords of technology and creation, since its launch. Through online/offline workshop management and exhibition planning production, he is practising “creating a place where chemical reactions occur” and “designing contexts that connect things from different fields.

https://loftwork.com/jp/people/kousuke_kinoshita -

Junya Iida

Loftwork Inc.

Creative DirectorAfter working as an engineer for a semiconductor company for eight years, Junya Iida moved to the UK to study art and design. He graduated from Central Saint Martins College of Arts and Design in London with a degree in Graphic Design. After returning to Japan, he worked as a graphic designer at SANDWICH, an art, architecture, and design company, before joining Loftwork in 2018.

After working as an engineer for a semiconductor company for eight years, Junya Iida moved to the UK to study art and design. He graduated from Central Saint Martins College of Arts and Design in London with a degree in Graphic Design. After returning to Japan, he worked as a graphic designer at SANDWICH, an art, architecture, and design company, before joining Loftwork in 2018.

-

An Kato

Loftwork Inc.

Creative DirectorBorn in Aichi Prefecture. Graduated from Nagoya University of Arts. My research theme at university was “Body and Clothing”.

Also involved in planning exhibitions and campus renovation projects.In 2021, I experienced the power of creativity through an internship at FabCafe Nagoya. Seeking to encounter new values created by various fields and creativity, she joined Loftwork.

Born in Aichi Prefecture. Graduated from Nagoya University of Arts. My research theme at university was “Body and Clothing”.

Also involved in planning exhibitions and campus renovation projects.In 2021, I experienced the power of creativity through an internship at FabCafe Nagoya. Seeking to encounter new values created by various fields and creativity, she joined Loftwork.

-

Emma Fukuwatari Huffman

Design-researcher

Emma graduated from the Kyoto Institute of Technology MA in Design in 2022. She works as a translator and interpreter in Design Projects since 2017. Currently, she produces and manages workshops at Mediamatic (Amsterdam) while continuing design research projects on the theme of repair and non-human relationships.

Emma graduated from the Kyoto Institute of Technology MA in Design in 2022. She works as a translator and interpreter in Design Projects since 2017. Currently, she produces and manages workshops at Mediamatic (Amsterdam) while continuing design research projects on the theme of repair and non-human relationships.

-

Date & Time

-

Fri, March 17, 2023 – Tue, March 21, 2023 11:00 – 18:00 UTC+09:00

-

Venue

-

Kyoto Saga University of Arts

View on Google Map -

Fee

-

free