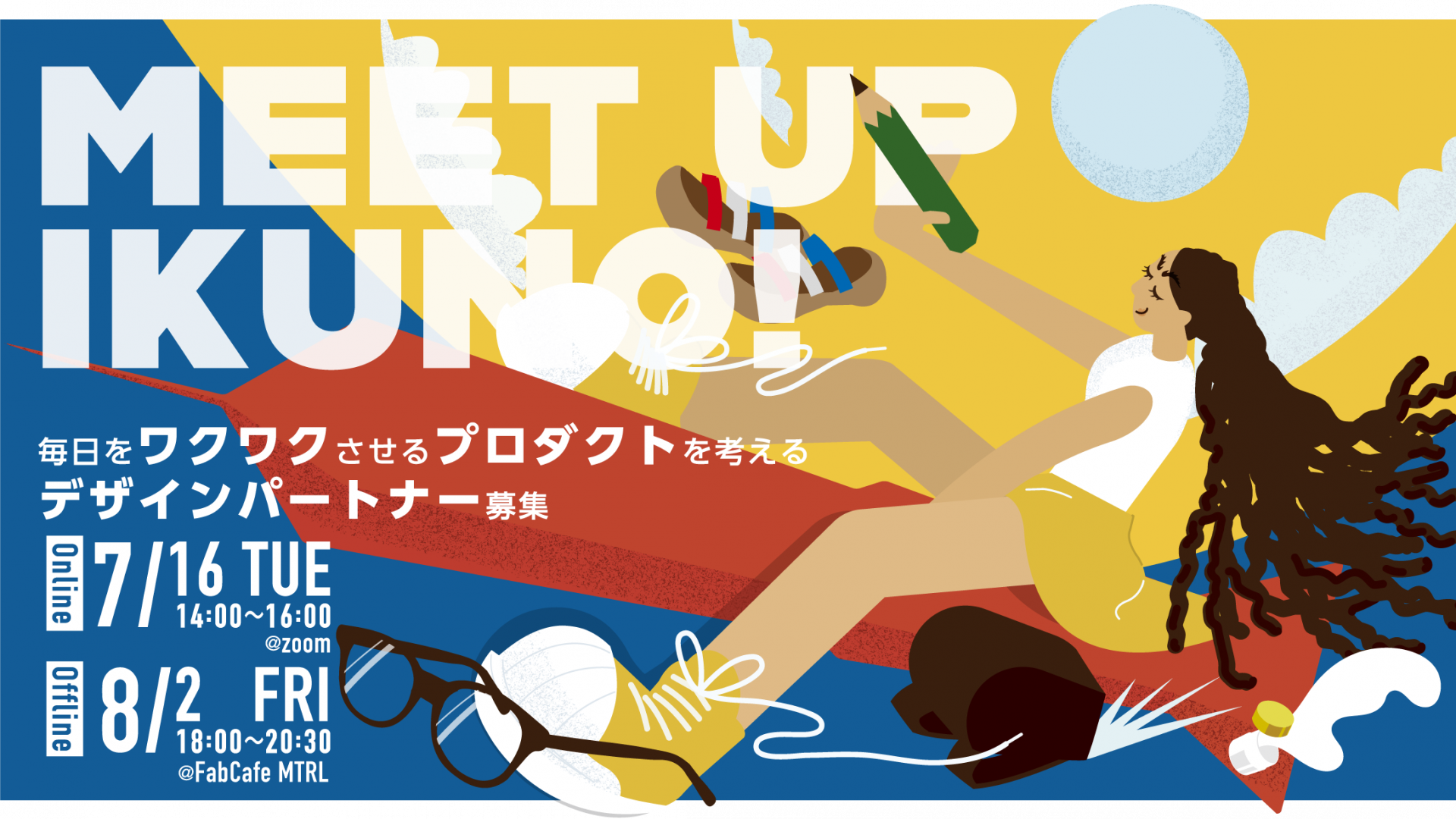

Meetup

- #Finished

- #Entrance Free

Tomoyasu Works Co.,Ltd. and the Ikuno Ward Office of Osaka City are seeking design partners for the "Ikuno Monodukuri Town Project," an exciting initiative to develop innovative products in collaboration with five manufacturing companies in Ikuno Ward. At this meetup, participants will receive a comprehensive project overview, including introductions to each participating company and the products they are interested in collaborating on. Participants will also have the opportunity to experience the products and technologies firsthand.

Fri, August 2, 2024 UTC+09:00

18:00 – 20:30

Please sign up via the Google Form by clicking the "Join" button.

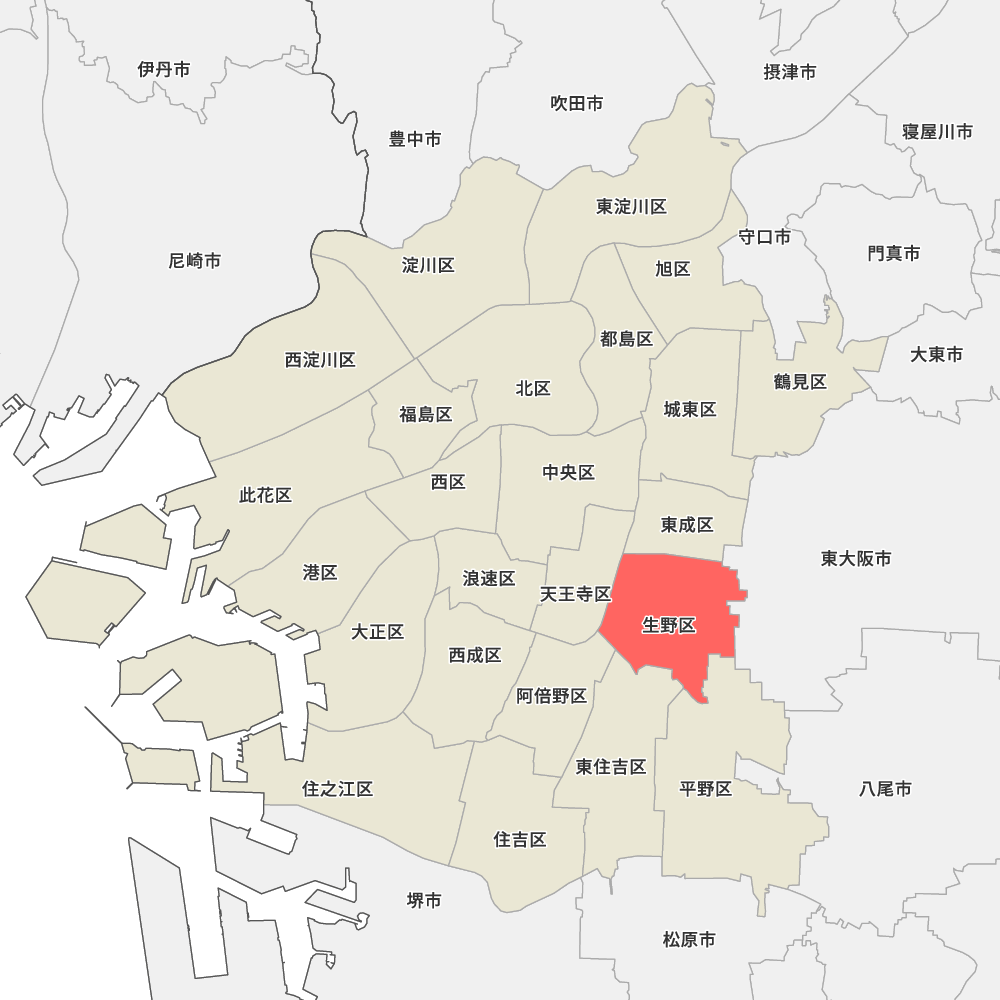

Located in the southeastern part of Osaka City, Ikuno Ward is renowned for its tourist attractions like Tsuruhashi and Koreatown. This vibrant area is a melting pot of cultures, with residents from Korea, China, Nepal, Vietnam, the Philippines, and Malaysia. Known as “the town of manufacturing,” Ikuno Ward is home to around 1,800 manufacturing companies that play a crucial role in supporting our daily lives.

Tomoyasu Works Co.,Ltd. and the Ikuno Ward Office of Osaka City are excited to announce the “Ikuno Monodukuri Town Project” This innovative initiative seeks design partners to join in developing everyday products in collaboration with five local manufacturing companies, all under the theme of “Enjoying Manufacturing.”

At this meetup event, creators will receive a comprehensive overview of the project. Additionally, each participating company will present their background and reasons for joining the project, and the products they aim to develop. We hope this event will spark inspiration and creativity, leading to groundbreaking

ideas.

*The event will be presented in Japanese.

Kunitoshi Yamaoka (CEO of Yamaoka Metal Mold Co.,Ltd.)

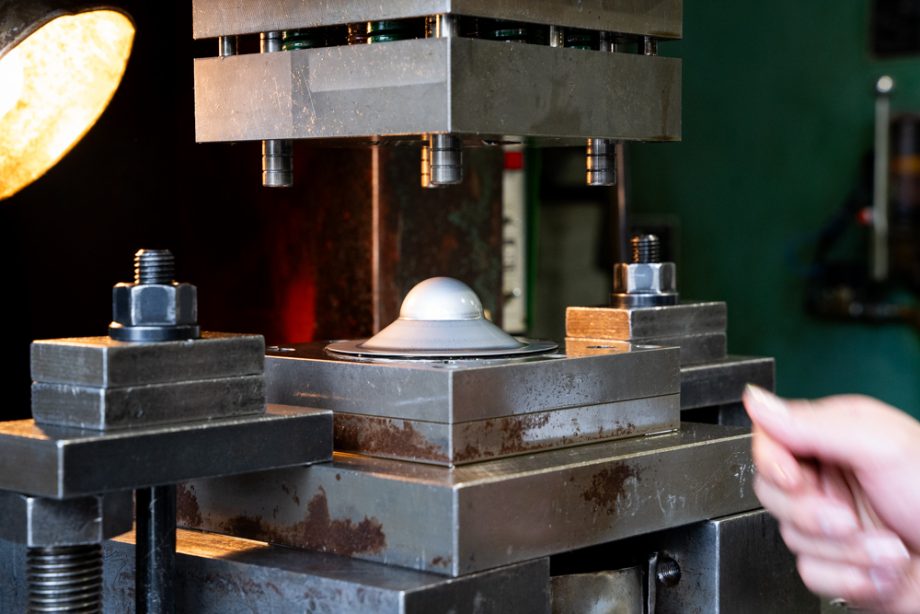

Since 1923, we have been specializing in manufacturing molds for eyeglasses, with a particular focus on sports sunglasses. These sunglasses feature numerous free-form surfaces, and we craft our molds to match these complex curves. We would be thrilled to collaborate with creators in discussing and creating plastic products with organic designs using our advanced mold technology.

Seietsu Kanazawa (CEO of Kanabi Co.,Ltd.)

Our story began in 1948 when my grandfather founded a soft vinyl materials shop. Over the years, we introduced lamination and embossing machines and have primarily focused on processing recycled vinyl sheets. Ikuno Ward has a rich history of small factories, where products are transported from one factory to another by truck until they are complete. These factories often specialize in specific processes. My goal is to break out of this mindset and build a narrative of “manufacturing,” demonstrating that even small, specialized factories can contribute to the creation of complete products.

Yanghee Lee(Executive Director of Gendai Kogyo Inc.)

・Description of What Gendai Kogyo Inc. Can Do: Bending Processing/ Cutting Processing/ Drilling Processing

・Types of processing equipment/ Explanation of what can be produced using this equipment

・Introduction of complete products: High-end brand displays in department stores/ Display shelves/ Signboards and Logos/ Interiors/ Model rooms by AQURA HOME/ Inserts

・Awards and Achievements:R bending (Minister of Health, Labour and Welfare Award) / Triple R bending (Grand Prize)

Yukihiro Kuga (Sales and Marketing Department, Kitao Cosmetics Co. Ltd.)

Kitao Cosmetics Co. Ltd. was founded in 1919 in Ikuno Ward. We are excited about the opportunity to collaborate on the visual design, including the concept, e-commerce site, and packaging. We aim to develop product packaging that clearly communicates our product’s value, even when displayed in variety stores. (The products can be selected in our company.) Japanese cosmetics have lost significant market share to Korean cosmetics in both retail stores and online sales. We want to launch a new line of Japanese cosmetics that stands apart from Korean products. Additionally, we hope to create a product with creators that will help us improve our e-commerce capabilities, an area where we currently face significant challenges.

Tomonori Takuwa (Manufacturing Manager of Sanei Metallic Manufacturing Co., Ltd)

Sanei Metallic Manufacturing Co., Ltd is more than just a press factory. We handle the entire production process in-house, from mold design and manufacturing, resin molding, and polishing, to cleaning, inspection, and assembly. We take pride in seeing projects through to the very end. Wouldn’t you like to work with a company like ours?

Join the meetup if you are…

- Interested in manufacturing in Ikuno Ward, Osaka.

- A designer or creator who wishes to collaborate with local businesses!

About Ikuno Monodukuri Town Project (IMT)

Application Overview:

- Application Period: July 1, 2024 (Monday) to August 30, 2024 (Friday)

- Deadline: 11 pm, Friday, August 30, 2024 (Japan Time)

For further details, please visit the AWRD website: https://awrd.com/award/monotown2024

-

Kunitoshi Yamaoka

CEO of Yamaoka Metal Mold Co.,Ltd.

Kunitoshi Yamaoka began working with 3D CADCAM during his university years to help his family business. At a time when 3D CAD was not widely used and with no one to guide him, he taught himself through trial. His younger brother, who majored in product design at art school, shared his interest in industrial design. Together, they dreamed of bringing their own products to market.

Traditionally, the mold manufacturing industry is reactive, creating items based on client orders, which made it challenging for Kunitoshi to realize his own ideas. However, the challenges of the COVID-19 pandemic and the influx of overseas products led to a decline in orders. In response, Kunitoshi decided to utilize the advanced processing technology developed in the mold manufacturing industry. In 2023, he partnered with local manufacturers in Ikuno Ward to launch their own brand, “molmena.”

Kunitoshi Yamaoka began working with 3D CADCAM during his university years to help his family business. At a time when 3D CAD was not widely used and with no one to guide him, he taught himself through trial. His younger brother, who majored in product design at art school, shared his interest in industrial design. Together, they dreamed of bringing their own products to market.

Traditionally, the mold manufacturing industry is reactive, creating items based on client orders, which made it challenging for Kunitoshi to realize his own ideas. However, the challenges of the COVID-19 pandemic and the influx of overseas products led to a decline in orders. In response, Kunitoshi decided to utilize the advanced processing technology developed in the mold manufacturing industry. In 2023, he partnered with local manufacturers in Ikuno Ward to launch their own brand, “molmena.”

-

Seietsu Kanazawa

CEO of Kanabee Co.,Ltd.

Growing up in a family-run business, Seietsu Kanazawa often helped out in the factory located on the first floor of his home. Although he disliked carrying heavy vinyl during his childhood, he decided to join the family business at the age of 30. While finding fulfillment in processing soft PVC, he believed there was more he could achieve. He is determined to take on new challenges to ensure both he and the company continue to grow and reach new heights.

Growing up in a family-run business, Seietsu Kanazawa often helped out in the factory located on the first floor of his home. Although he disliked carrying heavy vinyl during his childhood, he decided to join the family business at the age of 30. While finding fulfillment in processing soft PVC, he believed there was more he could achieve. He is determined to take on new challenges to ensure both he and the company continue to grow and reach new heights.

-

Yanghee Lee

Executive Director of Gendai Kogyo Inc.

Yanghee Lee previously worked for four years in sales and one year as a secretary at the Japanese branch of a Korean conglomerate. At the age of 31, he entered graduate school and graduated from the School of Management. Seven years ago, he joined the family business, Gendai Kogyo. Starting from scratch, he learned 2D and 3D CAD, spending four years developing and managing the production of architectural hardware. For the past three years, he has focused on management, continuously addressing the risks and challenges he analyzed during his graduate studies. Through trial and error, he has been leading various business improvement activities.

As the company celebrates its 34th anniversary, Yanghee is deeply committed to understanding the value of their renowned “bending” technology, which has been essential to their customers. Driven by the desire to use Gendai’s technology to benefit more people, he is dedicated to leading the company into its next stage by focusing on product development.

https://gendaikogyo.com/

https://www.instagram.com/gendaikogyo.1990Yanghee Lee previously worked for four years in sales and one year as a secretary at the Japanese branch of a Korean conglomerate. At the age of 31, he entered graduate school and graduated from the School of Management. Seven years ago, he joined the family business, Gendai Kogyo. Starting from scratch, he learned 2D and 3D CAD, spending four years developing and managing the production of architectural hardware. For the past three years, he has focused on management, continuously addressing the risks and challenges he analyzed during his graduate studies. Through trial and error, he has been leading various business improvement activities.

As the company celebrates its 34th anniversary, Yanghee is deeply committed to understanding the value of their renowned “bending” technology, which has been essential to their customers. Driven by the desire to use Gendai’s technology to benefit more people, he is dedicated to leading the company into its next stage by focusing on product development.

https://gendaikogyo.com/

https://www.instagram.com/gendaikogyo.1990 -

Yukihiro Kuga

Marketing and Sales Department, Kitao Cosmetics Co., Ltd.

Yukihiro Kuga has been working in the cosmetics industry for about 10 years. In his previous position, he was involved in manufacturer sales. At his current company, he is responsible for OEM production, sales of the company’s own brand, and overseas export operations. He specializes in selling hair care and skin care products, and he is well-versed in various distribution channels, including co-ops, beauty salons, and variety stores (such as Loft and Plaza). Yukihiro enjoys using cosmetics himself and regularly purchases and tests new products from other companies. He hopes to break away from the constraints formed over the past 10 years and engage in innovative product development without being bound by preconceived notions.

https://homei-nail.jp/

http://kitao.co.jp/

https://www.instagram.com/kitao_cosmetics/Yukihiro Kuga has been working in the cosmetics industry for about 10 years. In his previous position, he was involved in manufacturer sales. At his current company, he is responsible for OEM production, sales of the company’s own brand, and overseas export operations. He specializes in selling hair care and skin care products, and he is well-versed in various distribution channels, including co-ops, beauty salons, and variety stores (such as Loft and Plaza). Yukihiro enjoys using cosmetics himself and regularly purchases and tests new products from other companies. He hopes to break away from the constraints formed over the past 10 years and engage in innovative product development without being bound by preconceived notions.

https://homei-nail.jp/

http://kitao.co.jp/

https://www.instagram.com/kitao_cosmetics/ -

Tomonori Takuwa

Manufacturing Manager of Sanei Metallic Manufacturing Co., Ltd

Tomonori has a passion for manufacturing and aims to create an enjoyable and fulfilling environment at Sanei Metallic Manufacturing Co., Ltd.

Tomonori has a passion for manufacturing and aims to create an enjoyable and fulfilling environment at Sanei Metallic Manufacturing Co., Ltd.

-

IKUNO Ward Office, Osaka City

Ikuno Ward is located in the southeastern part of Osaka City and is a vibrant, multicultural community where people from about 80 countries live. Before World War II, it began developing as a town for manufacturing everyday items such as mirrors, eyeglasses, matches, and food products. During the period of rapid economic growth, industries like metal processing and the manufacturing of rubber and vinyl products flourished. Despite facing challenges such as cost competition and a shortage of successors, the area is currently engaging in new manufacturing initiatives focused on IT, design, welfare, and the environment.

Ikuno Ward is located in the southeastern part of Osaka City and is a vibrant, multicultural community where people from about 80 countries live. Before World War II, it began developing as a town for manufacturing everyday items such as mirrors, eyeglasses, matches, and food products. During the period of rapid economic growth, industries like metal processing and the manufacturing of rubber and vinyl products flourished. Despite facing challenges such as cost competition and a shortage of successors, the area is currently engaging in new manufacturing initiatives focused on IT, design, welfare, and the environment.

-

Tomoyasu Works Co., Ltd. (Tomoyasu Seisakusyo)

Founded in 1948, Tomoyasu Seisakusho started with a single screw. Leveraging its strengths as a traditional manufacturing company, it develops and sells original products and operates an e-commerce business offering around 40,000 interior items. Additionally, the company has expanded into various other ventures, including a café, construction business, media business, rental space business, and town planning projects.

With the slogan “Play with Life,” Tomoyasu Seisakusho aims to continuously provide products and services that offer better lifestyle choices tailored to each individual’s personality. Their vision is to “Add Colors to everyone’s Life” – bringing vibrancy to the lives of people around the world.

Founded in 1948, Tomoyasu Seisakusho started with a single screw. Leveraging its strengths as a traditional manufacturing company, it develops and sells original products and operates an e-commerce business offering around 40,000 interior items. Additionally, the company has expanded into various other ventures, including a café, construction business, media business, rental space business, and town planning projects.

With the slogan “Play with Life,” Tomoyasu Seisakusho aims to continuously provide products and services that offer better lifestyle choices tailored to each individual’s personality. Their vision is to “Add Colors to everyone’s Life” – bringing vibrancy to the lives of people around the world.

-

18:00 – 18:10

-

What’s "IKUNO MONOTOWN Project”?

-

18:10 – 18:25

-

"Injection Molded Products Crafted from Molds that Emphasize Elegant Curves" by Yamaoka Metal Mold Co.,Ltd. / Q&A

-

18:25 – 18:40

-

"Manufacturing from Small Factory" by Kanabi Co.,Ltd. / Q&A

-

18:40 – 18:55

-

"Expanding the possibilities of bending" by Gendai Kogyo Inc.

-

18:55 – 19:10

-

"The Third START" by Kitao Cosmetics Co. Ltd. / Q&A

-

19:10 – 19:25

-

"A Company that Enjoys Manufacturing: Sanei Metallic Manufacturing Co., Ltd" by Sanei Metallic Manufacturing Co., Ltd / Q&A

-

19:25 – 20:30

-

Networking

-

Date & Time

-

Fri, August 2, 2024 18:00 – 20:30 UTC+09:00

-

Venue

-

FabCafe MTRL

東京都渋谷区道玄坂1-22-7 道玄坂ピア2F

京王井の頭線 神泉駅 南口 徒歩3分

JR 渋谷駅 徒歩10分

03-6416-9190

View on Google Map -

Fee

-

Free Non-alcoholic drinks included.

-

Capacity

-

30

Please sign up via the Google Form by clicking the "Join" button.