Project Case

July 25, 2022

FabCafe Global Editorial Team

In 2018 and 2019, FabCafe Tokyo and FabCafe Hida planned and implemented a study abroad program for the New York-based University at Buffalo School of Architecture and Planning. The program provided a valuable opportunity to explore Tokyo’s latest design trends, learn about Hida’s unique history of carpentry and craft, and prototype architectural solutions for the challenges the local wood manufacturing industry is currently facing.

In the third edition of the program, students were not able to travel to Japan due to Covid-19. They were not the only ones facing this obstacle: since the beginning of the pandemic, international teams around the world have encountered fluctuating travel restrictions and remote collaboration has become an essential asset for universities and businesses alike.

Far from disappearing once Covid-19 is over, this trend is expected to become the general way to work in the near future, but the necessary technologies and systems still require further development. The 2022 program took on the challenge of bridging separate locations and time zones to test how global teams can work together using Augmented Reality (AR) and 3D.

Program participants working from the School of Architecture and Planning campus.

FabCafe Tokyo and Hida proposed an efficient workflow that allowed stakeholders to collaborate remotely from Japan and the US.

Participants sent 3D models to the local carpenters, who then used HoloLens to project them onto the wood blocks during the cutting and assembling phase. Through a trial-and-error process, the team identified the difficulties, as well as the potential, of using AR and 3D technologies in architectural design.

Along the way, students and craftsmen gained insight into how this system may be better standardized in the future, and also provided feedback to the software developers.

Project stakeholder map.

The possibilities of AR have been widely explored in the entertainment field, but through this program, FabCafe and the University at Buffalo’s School of Architecture and Planning proved that there is still much potential left to develop in sectors like space design, product design, engineering, and manufacturing, among others.

New possibilities for Augmented Reality.

Students used LiDAR data provided by FabCafe Hida to design small structures, pavilions, furniture, and sculptural objects in 3D and AR with a program called Fologram. Then, they sent the models to Hida carpenters, who wore HoloLens on-site to project the AR models onto the woodblocks, and cut and assembled them accordingly.

Throughout the process, Hida carpenters provided feedback on the challenging points so that students could refine their designs and develop a “situated use of technology”; that is, a use of technology that places human interaction at its center.

Concept development (Balance project by Lisa Liang, Ryan Philips, and Cam Ziegler).

Students created 3D data for Hida carpenters.

Carpenters asked for a chainsaw 3D model to be included in the AR projection.

Carpenters tested various types of cuts and provided feedback to students.

Through a trial and error process, the operation workflow was refined, earning more accurate results.

At the end of the program, students presented their projects at the University at Buffalo. Fologram software developers virtually attended the presentation to see how their product had been used during the project.

Click here to watch more photos and videos of the different projects!

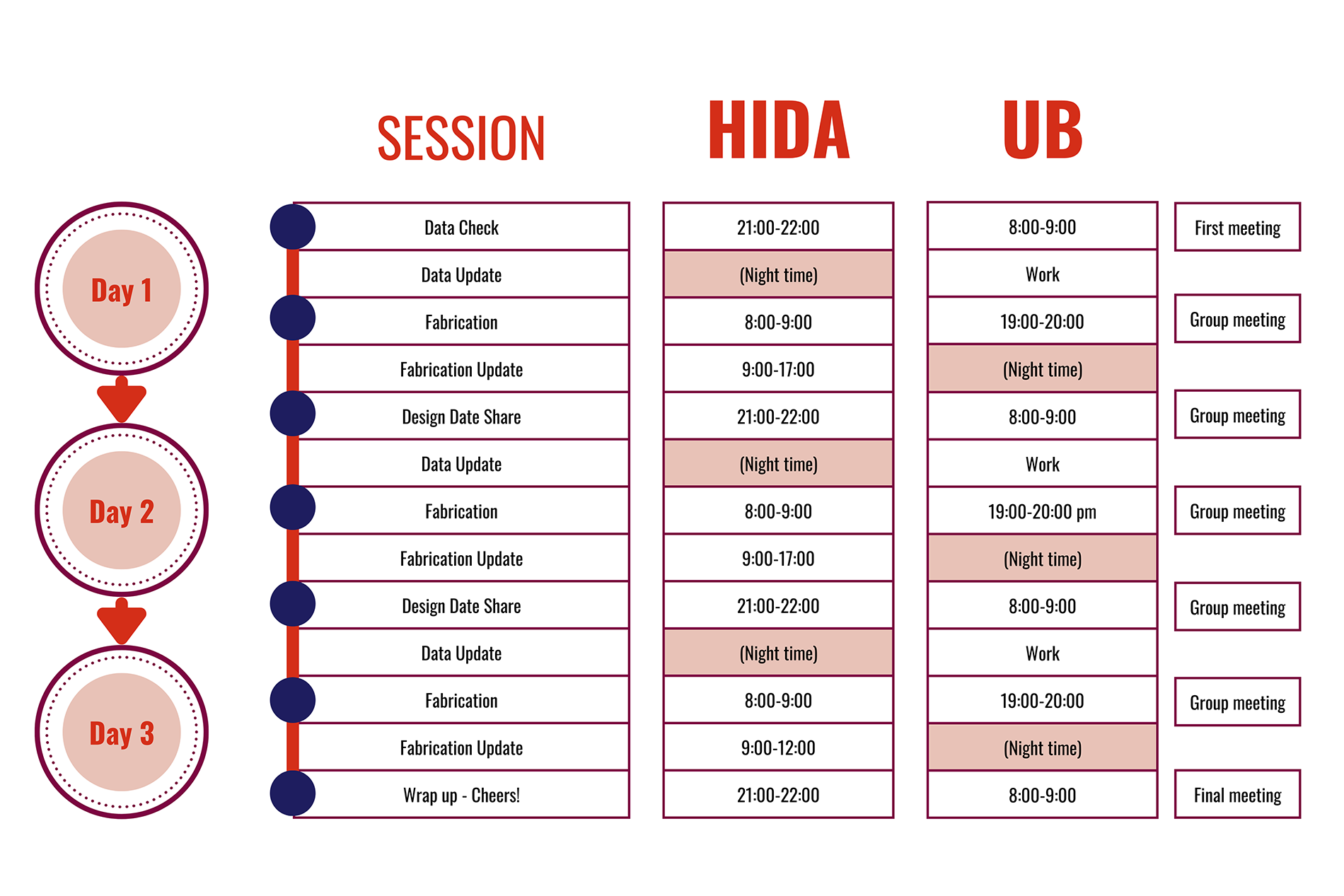

The three-day program implemented a swift communication flow that took advantage of the time-zone difference. As a result, the team was able to work 24 hours non stop!

The international team schedule. Students provided data, received feedback from carpenters, and updated their models. Group meetings were held via Zoom.

What can we do for you?

Contact us if you are interested in…

- Testing the application of AR, 3D, and other software to your business

- Testing new manufacturing processes through prototyping

- Upskilling your workforce through hands-on learning

- Implementing on-site, remote, or hybrid learning and fabrication programs

- And more!

Project Outline

- Project client: University at Buffalo School of Architecture and Planning

- Project time: March to May 2022

- Project leaders: Daiki Kanaoka (FabCafe Tokyo), Kotaro Iwaoka, Hideaki Asaoka, Kazunori Yanagi (Hidakuma, Team by the forest), Nicholas Bruscia (University at Buffalo)

-

FabCafe Global Editorial Team

This articles is edited by FabCafe Global.

Please feel free to share your thoughts and opinions on this article with us.

→ Contact usThis articles is edited by FabCafe Global.

Please feel free to share your thoughts and opinions on this article with us.

→ Contact us